INKJET PRINTING ・ DIGITAL PRINTING ・ LASER MARKING

Depending on the quantity, color variations and surface type, different printing services including inkjet printing, silkscreen printing, laser marking or CNC engraving may be suitable.

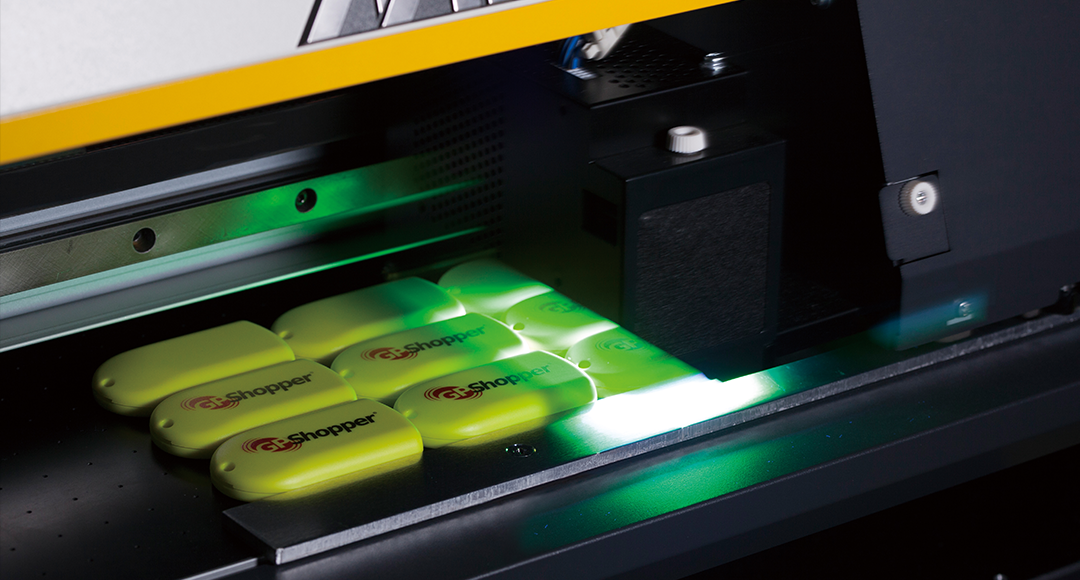

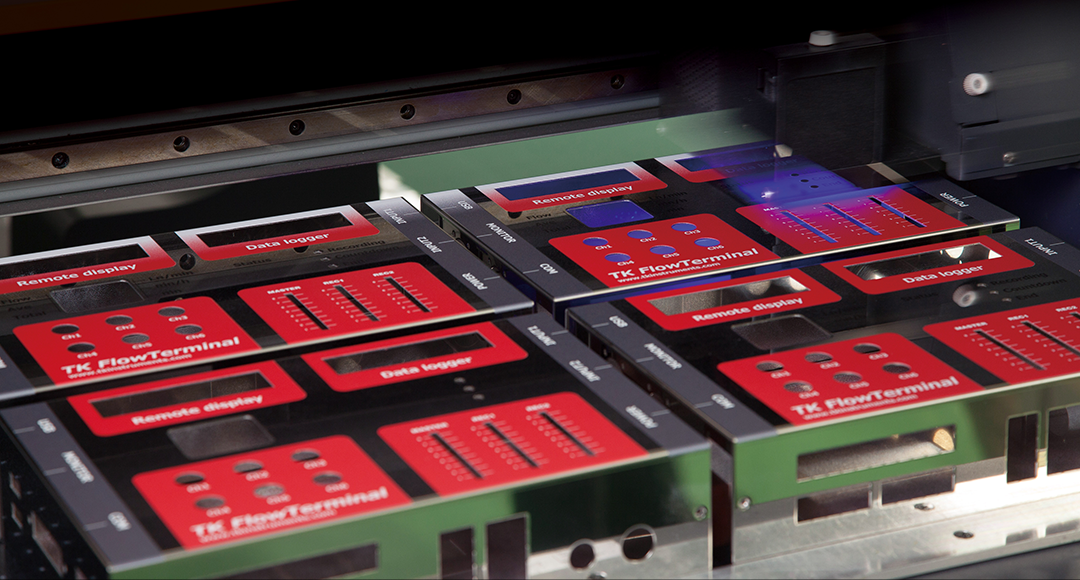

INKJET PRINTING ・ DIGITAL PRINTING

What is inkjet printing?

It is a type of computer printing that recreates a digital image by propelling droplets of ink onto the matter surface.

Compared to silk-screen printing, it utilizes a vector file instead of a physical print board, and has a significantly lower initial cost. Additionally, it is also cost efficient for small and medium batch quantity.

Furthermore, inkjet printing is not only able to print multiple colors at the same cost, but also realize color gradation, generating a picture-like print tone.

INKJET PRINTING - VIDEOS

Small plastic cases - Printing

IP65 plastic boxes - Printing

Raspberry Pi cases - Printing

Extruded aluminium - Printing

Aluminium panels - Printing

Stainless steel boxes - Printing

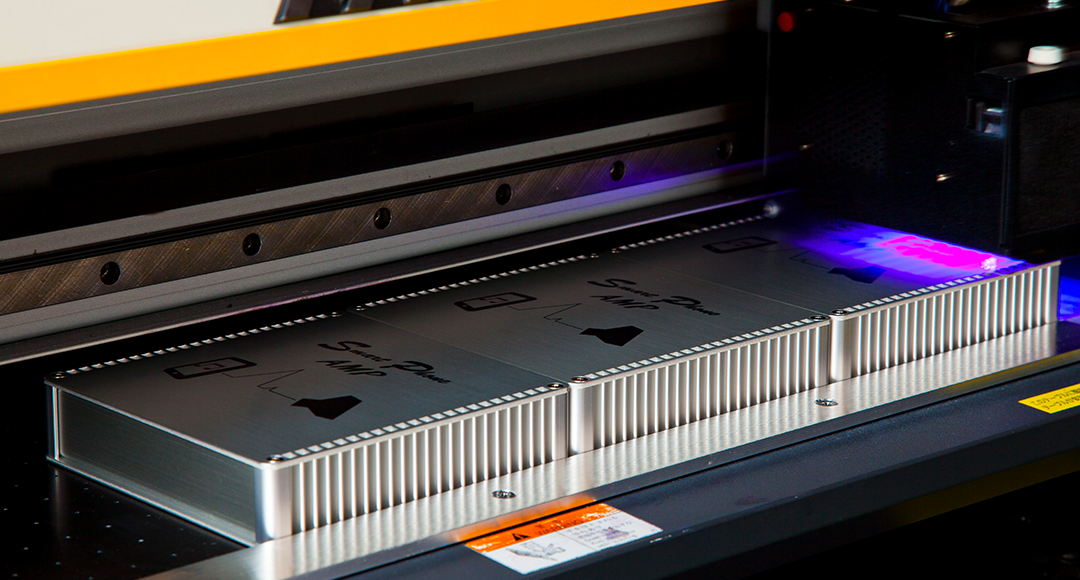

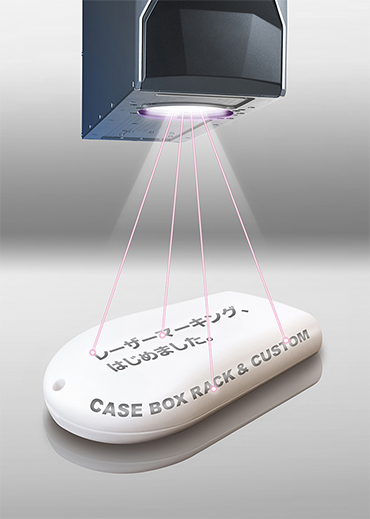

LASER MARKING

What is laser marking?

It is a type of computer marking that utilizes laser to perform markings onto the matter surface, allowing melting, scorching, peeling off, grinding or oxidizing irradiated spots on the material.

Latest 3D focus control laser marker enables accurate markings on the surface.

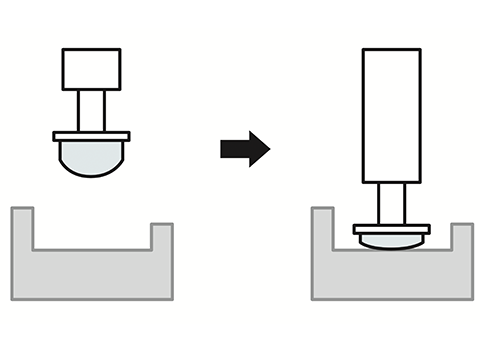

Laser marking can be performed on the curved surfaces or surfaces where the height difference exist where inkjet printing or silkscreen printing can hardly be done.

Compared to silk-screen printing, it utilizes a vector file instead of a physical print board, and has a significantly lower initial cost.

Laser marking can be performed on curved surfaces,

or surfaces where there is substantial height difference.

LASER MARKING - VIDEOS

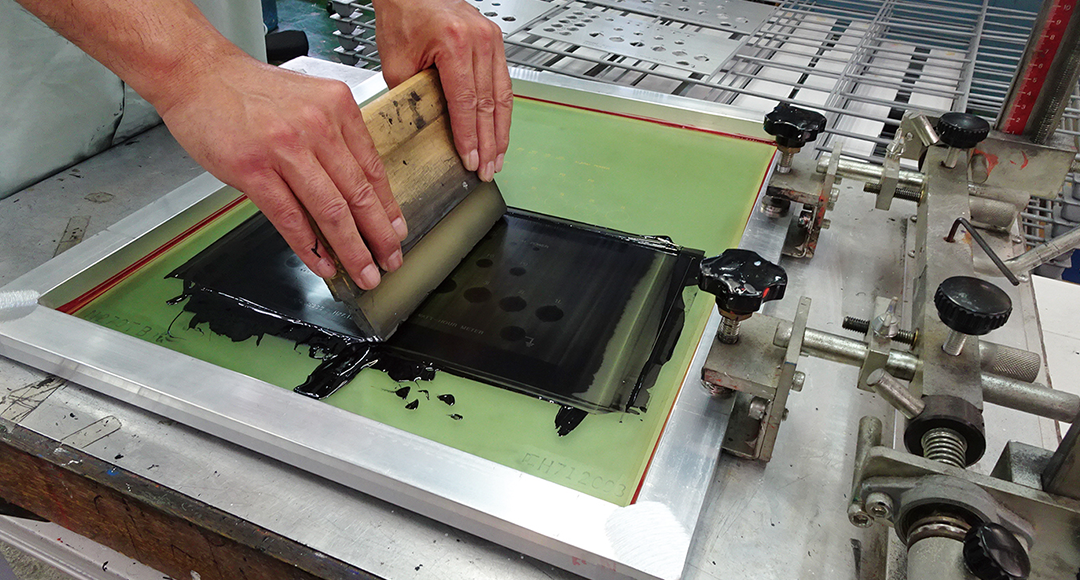

SILK SCREEN PRINTING

What is silk-screen printing?

It is a stencil method of printmaking in which a design is imposed on a screen of silk or other fine mesh, with blank areas coated with an impermeable substance, and ink forced through the mesh onto the printing surface.

Although generally having a higher initial cost due to requiring a creation of the print data and manufacturing of a board/mesh, it is however an extremely cost-efficient method for mass/large batch printing in a single color.

SILKSCREEN PRINTING - VIDEO

Silk screen printing

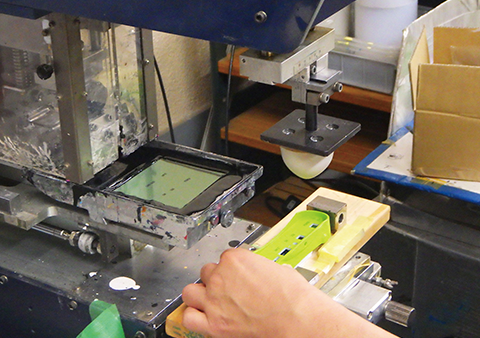

PAD PRINTING (Tampography)

What is pad printing?

It is also called tampography, a printing process that can transfer a 2-D image onto a 3-D object using an indirect offset (gravure) printing process via a silicone pad onto a substrate. Elastic silicone pad enables to print even on the curved surface or the surface where the height difference exists.

Pad Printing is cost-efficient method for mass/large batch printing in a single color onto the surface where height difference exists. For smaller quantity, laser marking is more cost-efficient.

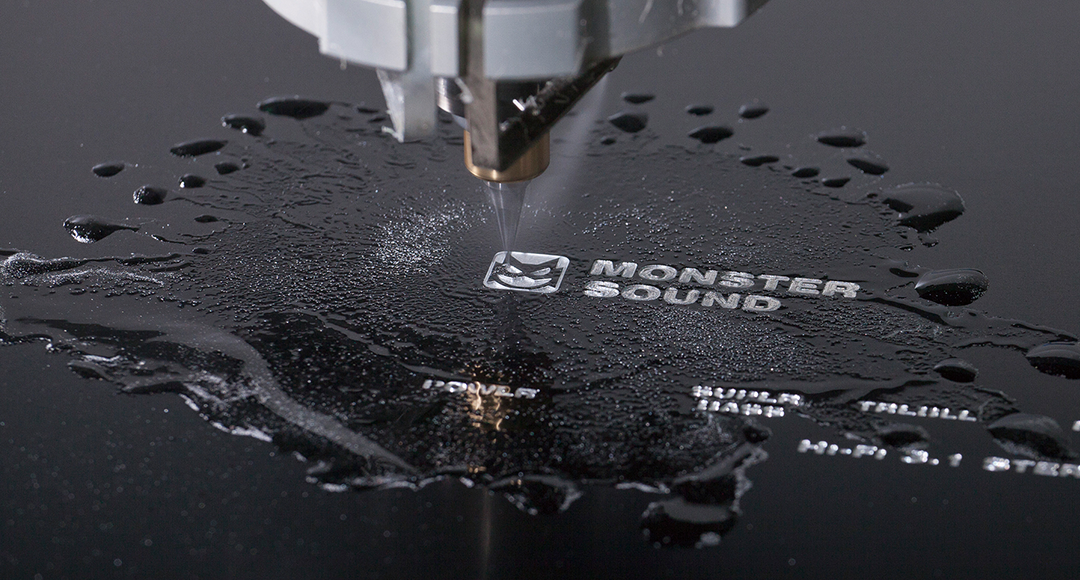

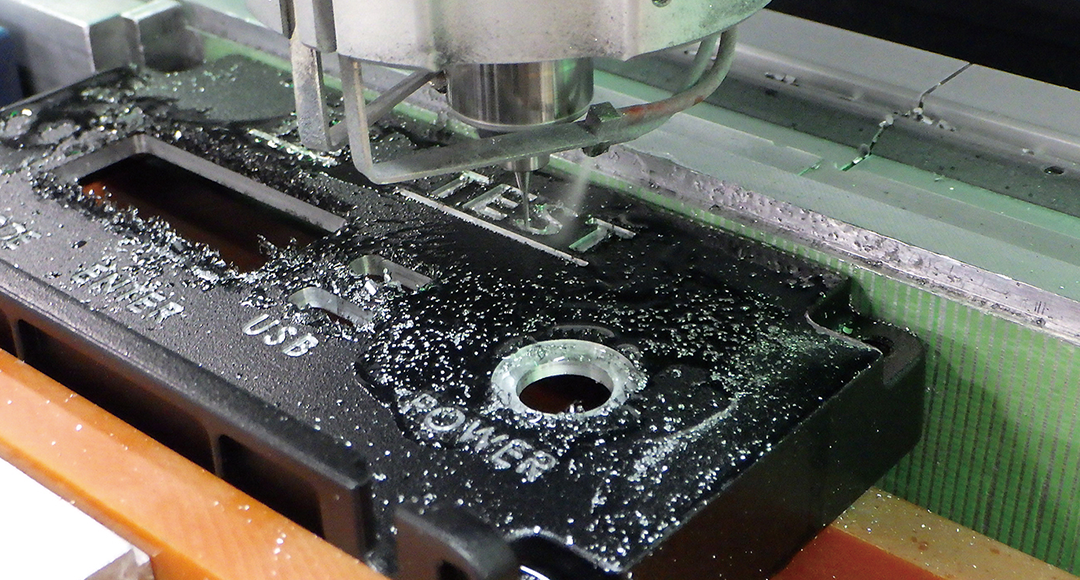

CNC ENGRAVING

By having the drill-head slightly milling the surface, the engraving of fine text or complex designs is able to be performed on a variety of surfaces, be it flat, curved, and more.

Due to the insertion of the ink into the hollowed area, it is one of the most reliable form of printing in terms of ink peeling durability.

In addition, black anodized enclosures can be engraved, and having their underlying material exposed which can function as either text or logo.

Recommended to be utilized with aluminium die-cast type products which have high tolerance variances.